Degreasing and surface preparation are much-used in industrial fields. They are not only a part of the process of painting and plating of metals/plastics, but also of other production processes which involve degreasing of products and handling technologies.

Our main specialization is manufacturers of unit production who have a portfolio of products that vary not only in shape but also dimension.

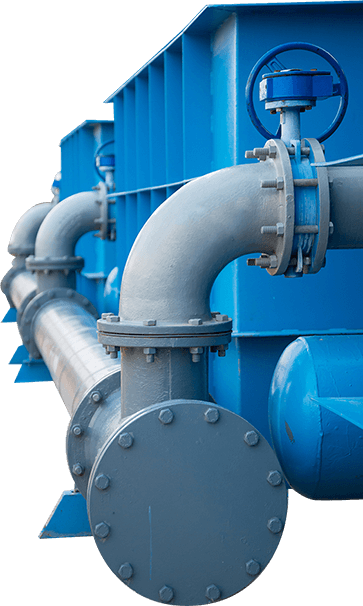

We are able to offer such clients a variety of boxes for high-pressure degreasing as well as small baths for immersion degreasing.

These are always designed individually according to the customer’s requirements. The actual washing of products is operated manually with the help of high-pressure units.

The largest workspace dimensions of the boxes are 10 x 5 x 4 metres (l x w x h). You can choose from enclosed solutions or those with a single side open, material being loaded into them with the help of a trolley or on a suspension rail.

Thanks to the recirculation unit you will achieve a lowering of consumption of wash chemicals and a reduction in waste water production which ultimately leads to a reduction of running costs for degreasing.

Immersion bath lines are most commonly used in the surface treatment of large quantities of small materials. They not only serve for pre-treatment of surfaces but, for example, for galvanized plating.

Thanks to our many years’ experience we are highly flexible and are able to produce any given bath from material which is best suited to the operation involved. The most commonly used materials are polypropylene or, where required, polyethylene, PVC, and PVDF.

For customers with a consistent product range (unchanging in shape and dimension) we offer our automatic chamber machine for high-pressure washing. Along with other operations such as phosphating or pickling, this process is fully automated.

Control of the operations of the chamber machine can be adjusted to allow the selection of several different programs. These combine a variety of operations and the length of time that they last. The dimensions of the machine are always designed on an individual basis.